What is the Form U3C for the state of Kansas?

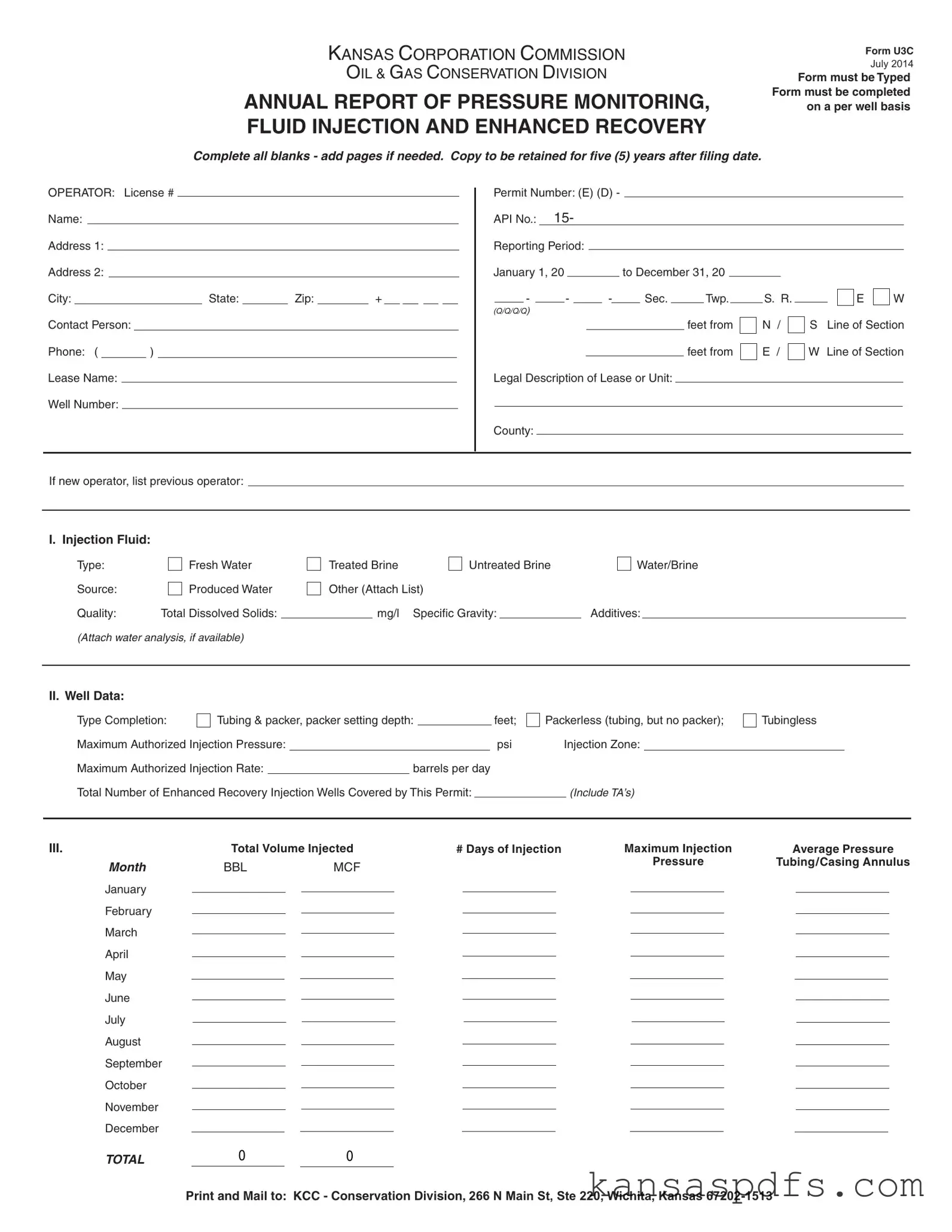

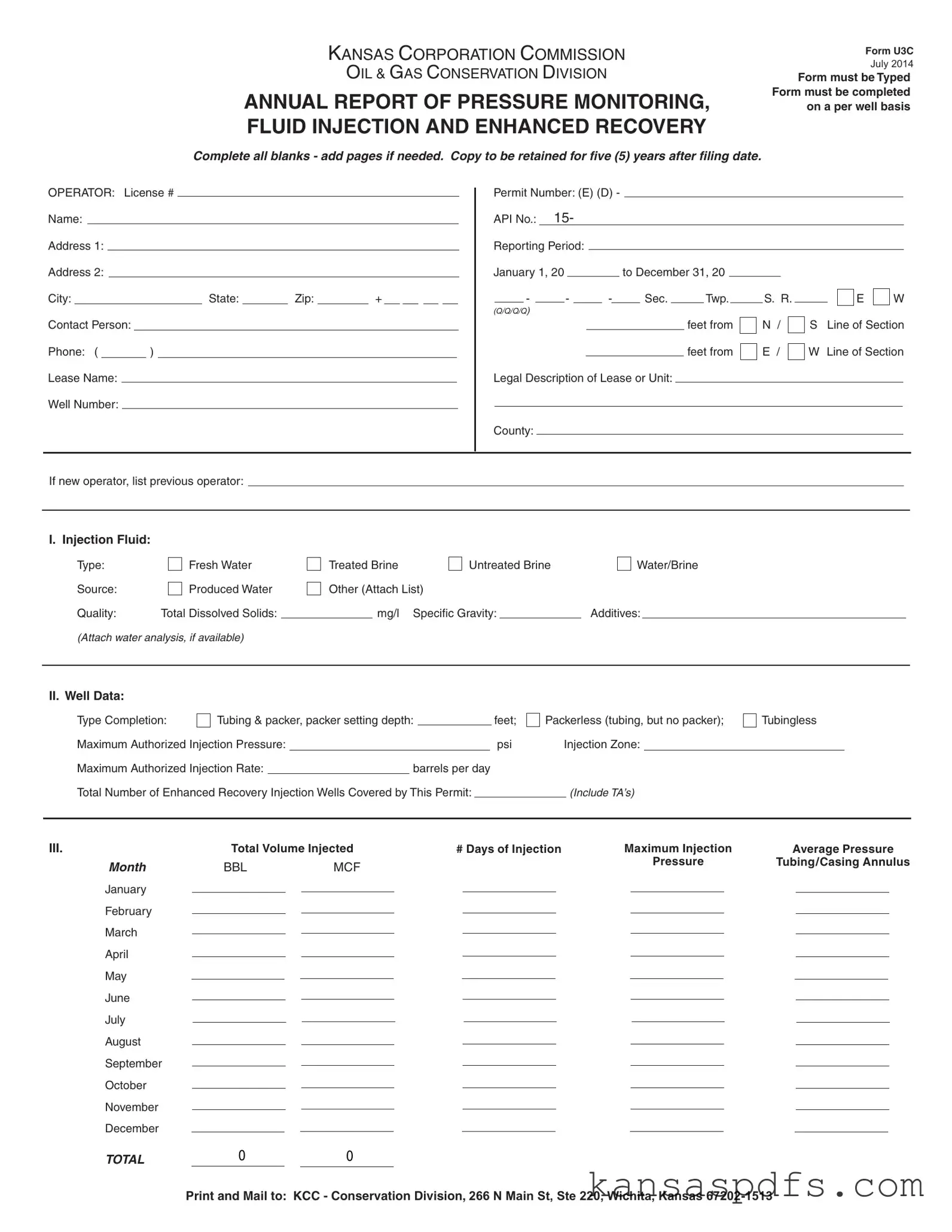

Form U3C is a required annual report filed with the Kansas Corporation Commission's Oil & Gas Conservation Division. Its main purpose is to document and monitor pressure, fluid injection, and enhanced recovery activities for oil and gas wells in Kansas. Operators of such wells must provide comprehensive details per well basis, including information on injection fluids, well data, and the volume of fluid injected throughout the reporting period. This form ensures that all operations are conducted within the regulatory frameworks established for environmental and public safety.

How should Form U3C be filled out and submitted?

The instructions on the form state that it must be typed, indicating that handwritten submissions may not be accepted. Each section of the form requires specific details about the well's operation including the type of injection fluid used, the source and quality of the fluid, well data like the type of completion, and maximum authorized injection pressure and rate. Additionally, a monthly breakdown of the total volume injected and the number of days of injection is required. Once completed, the form should be printed and mailed to the Kansas Corporation Commission Conservation Division at the provided address in Wichita, Kansas. Operators are also advised to retain a copy of the form for five years after the filing date for their records.

Who needs to file Form U3C in Kansas?

Any operator of an oil or gas well in Kansas that engages in pressure monitoring, fluid injection, or enhanced recovery practices is required to file Form U3C. This includes a range of operators from those managing a small number of wells to large-scale producers. The requirement underscores the importance of maintaining oversight on activities that could potentially impact the state's oil and gas reserves and environmental health. Both new operators of existing wells and those continuing operations must submit this form annually to remain compliant with state regulations.

What information do you need to prepare before filling out Form U3C?

Before filling out Form U3C, operators need to gather comprehensive data about each well covered by the permit. This includes the license number, well number, and permit number, along with the well's location and legal description. Information on the injection fluid—such as type, source, quality, and any additives used—must also be prepared. Detailed well data is necessary, including the type of completion, packer setting depth, maximum authorized injection pressure, and rate. Finally, an accurate record of the volume of fluid injected each month, including the number of days of injection and any changes in pressure, must be compiled. Having this information ready beforehand will streamline the process of completing the form accurately.